Products

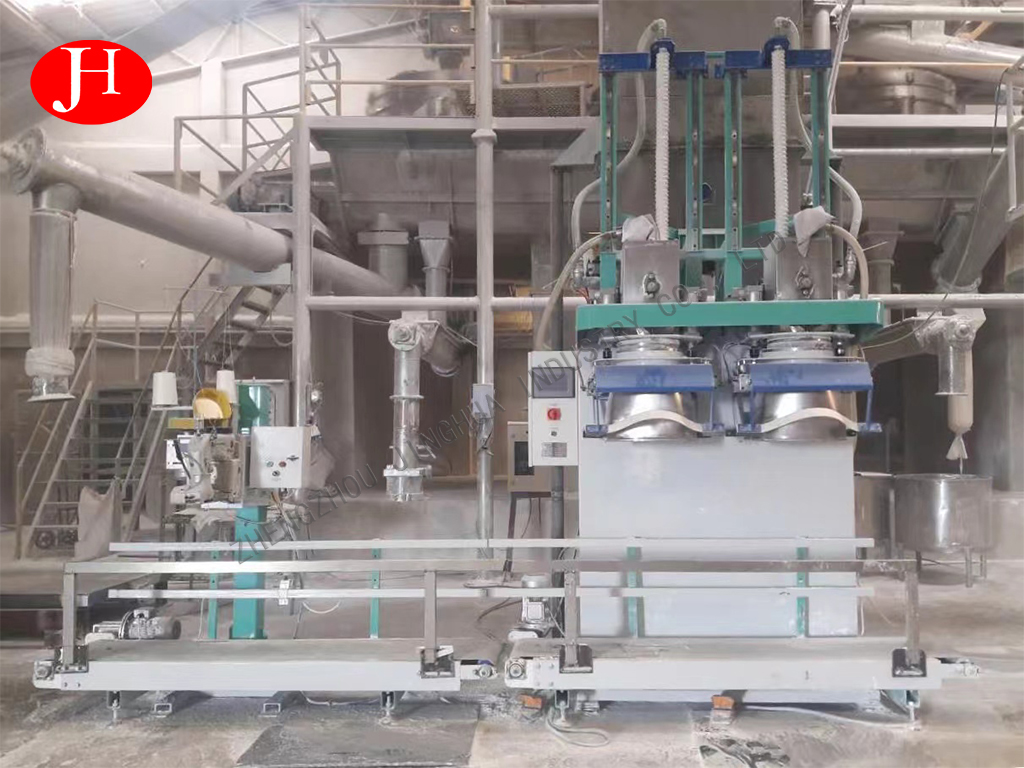

Packing Machine

Main technical parameters

|

Specification |

JHTB-5 |

JHTB-25 |

JHTB-50 |

|

Weighing ranges(Kg) |

5~10 |

20~25 |

20~50 |

|

Yield(packets/hour) |

150~600 |

150~500 |

300~400 |

|

Dividing the value(g) |

5 |

10 |

10 |

|

Power(Kw) |

4 |

4 |

4 |

|

Package size(mm) |

1750*1000*2200 3100*800*650 |

1750*1000*2200 3100*800*650 |

1750*1000*2200 3100*800*650 |

|

Total weight(kg) |

550 |

550 |

550 |

Features

- 1A fast, slow, speed, three speed feeding mode, AD processing technology with high speed, anti-interference technology, automatic error correction and compensation technology, accurate measurement, stable and reliable performance.

- 2According to different characters of different materials, the pumping, the gas material of gas extraction, convenient packing and transportation and storage bags. Improve food shelf life.

- 3For good fluidity material (such as starch) to take a special way of feeding, fast cutting flow system, to ensure that the measurement is accurate, stable and reliable performance.

- 4Lift the bag structure to ensure that the packaging vertical fall into the conveyor, reduce labor intensity and improve the working environment.

Show Details

The sensor of the packaging machine is subjected to the action of pressure to produce a micro - variable signal, which is processed by the computer. When the computer is activated by the external work signal, the feeder is controlled to feed the material quickly into the packaging bag. When the fast feeding ration is reached, the fast feeding is stopped, and the cylinder of the vibrating bag vibrates the packing material, and then the optimal feeding department is entered.

When the set ration of slow feeding is reached (ration _ drop), stop the slow feeding and loosen the bag holder, etc. Such a cycle of work to achieve automatic quantitative packaging. Press the stop switch if you need to stop working.

Scope of Application

Glutinous rice flour, corn starch, potato starch, tapioca starch, modified starch, gluten powder, dextrin and other starch enterprises.