Products

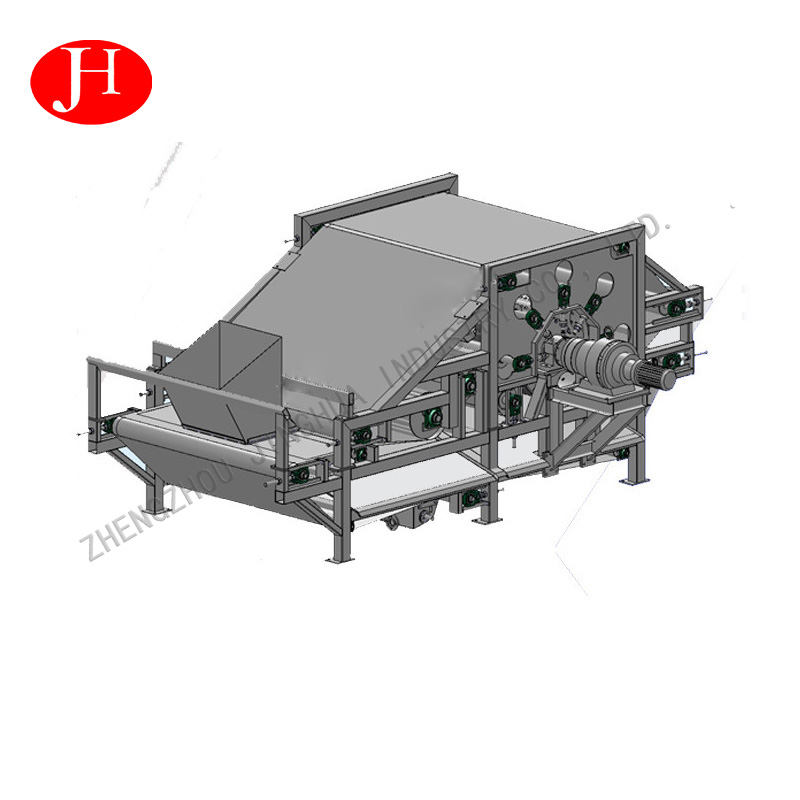

Fiber Dehydrator for Starch Processing

Main technical parameters

|

Model |

Power (Kw) |

Filtrating strap width (mm) |

Filtrating strap speed (m/s) |

Capacity(Before dehydrated)(kg/h) |

Dimension (mm) |

|

DZT150 |

3.3 |

1500 |

0-0.13 |

≥5000 |

4900x2800x2110 |

|

DZT180 |

3.3 |

1800 |

0-0.13 |

≥7000 |

5550x3200x2110 |

|

DZT220 |

3.7 |

2200 |

0-0.13 |

≥9000 |

5570x3650x2150 |

|

DZT280 |

5.2 |

2800 |

0-0.13 |

≥10000 |

5520x3050x2150 |

Features

- 1Product is independently developed by company, with the scientific research efforts of Henan University of Technology.

- 2Wedge-shaped feeder can ensure materials evenly distributed on the filtrating strap with thickness being adjustable.

- 3Dehydrated rolling system made seamless tube and wrapped by high quality wear-resistant rubber, It`s reliable with long service life.

Show Details

The potato residue feed hopper is flatly laid on the lower filter belt through the wedge-shaped feeding section.

Then the potato residue enters the pressing and dehydrating area. The potato residue is evenly distributed between the two filter belts and enters the wedge zone and begins to compress and dehydrate. Afterwards, the potato residue is held by the two filter belts, which rise and fall for several times. The positions of the inner and outer layers of the two filter belts on the roller are constantly changing, so that the potato residue layer is constantly dislocated and shear, and a large amount of water is squeezed out under the tension force of the filter belt. Then the potato residue enters the pressing and dewatering area. Under the action of several pressing rollers on the upper part of the driving roller, dislocation shear and extrusion are continuously produced.during the pressing process, the potato dregs are easily removed from the filter belt.

The potato residue is sent to the scraping device through the reversing roller, and after being scraped off by the scraping device, it enters the subsequent section.

Scope of Application

Sweet potato starch, tapioca starch, potato starch, wheat starch, corn starch, pea starch, etc. (starch suspension) starch production enterprises.