Products

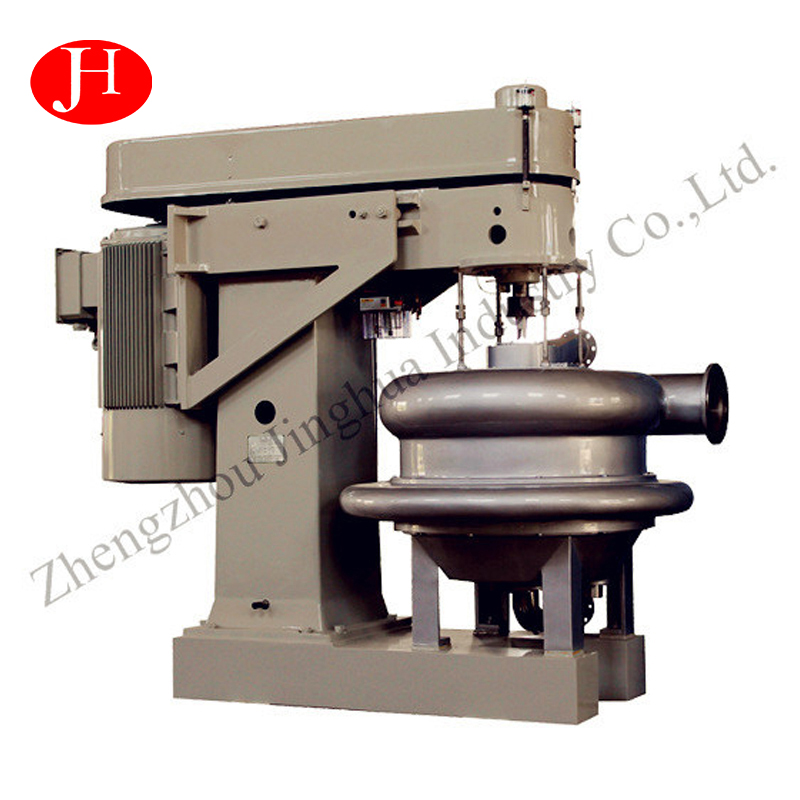

Disc Separator Machine

Main technical parameters

|

Main parameter |

DPF450 |

DPF530 |

DPF560 |

|

Bowl Inner Diameter |

450 mm |

530 mm |

560 mm |

|

Bowl Rotating Speed |

5200 r/min |

4650 r/min |

4800 r/min |

|

Nozzle |

8 |

10 |

12 |

|

Separating Factor |

6237 |

6400 |

7225 |

|

Throughput Capacity |

≤35m³/h |

≤45m³/h |

≤70m³/h |

|

Motor Power |

30 Kw |

37Kw |

55 Kw |

|

Overall Dimension (L×W×H) mm |

1284×1407×1457 |

1439×1174×1544 |

2044×1200×2250 |

|

Weight |

1100kg |

1550kg |

2200kg |

Features

- 1Disc separator is mainly used for starch production separating, concentrating and washing starch and protein in starch processing industry .

- 2The machine can also be applicable to the pharmaceutical, chemical and food industries for producing of material sources which are adapted to functions of this machine.

- 3The equipment adopts all stainless steel structure to effectively avoid the pollution of materials

- 4High rotating speed , high separating factor , low power and water consumption.

Show Details

Gravity arc sieve is a static screening equipment, which separates and classifies wet materials by pressure .

The slurry enters the concave screen surface from the tangential direction of the screen surface at a certain speed (15-25M/S) from the nozzle. The high feeding speed causes the material to be subjected to centrifugal force, gravity and the resistance of the screen bar on the screen surface. the role of When the material flows from one sieve bar to another, the sharp edge of the sieve bar will cut the material.

At this time, the starch and a large amount of water in the material pass through the sieve and become the undersize, while the fine fiber residue flows out from the end of the sieve surface and becomes the oversize.

Scope of Application

Disc separator is mainly used in the starch production that coming from maize, manioc, wheat, potatoes or other material sources for separating, concentrating and washing of starch and protein.